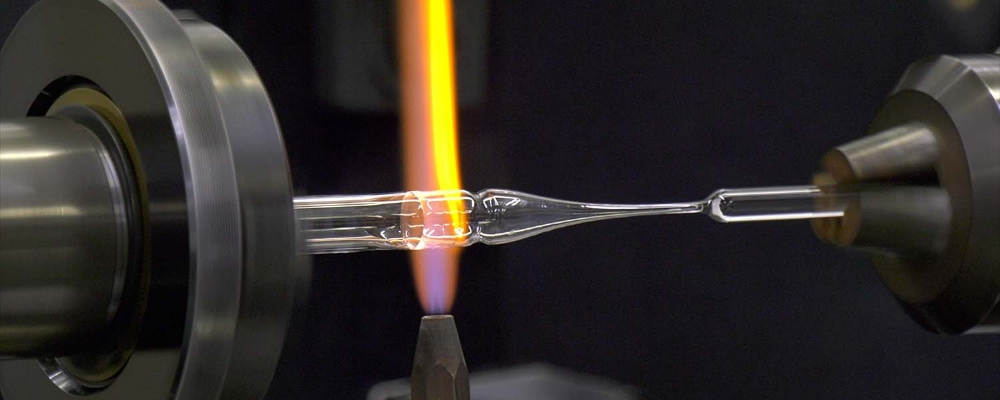

Flame WorkingThe Origin of Onizuka Glass

Our craft begins with the art of flame working—the precise control of gas burner flames. Glass comes in many varieties, each with unique properties, while the flame itself is sensitive to environmental factors like temperature and humidity. Our skilled artisans masterfully adjust the flame for each type of glass, creating high-quality products under optimal conditions. This expertise, built on years of experience, is the hallmark of our craftsmanship.

Graded Seal Processing

We specialize in "Graded Seal Processing," an advanced technique for joining glasses with different coefficients of thermal expansion. By using an intermediate glass to create a gradual transition, this method enhances the durability and reliability of the seal. This allows us to create exceptionally robust glass components suitable for a wide variety of applications.

Dissimilar Material Joining

Our expertise extends to joining dissimilar materials, seamlessly bonding glass to various metals, including tungsten (W), molybdenum (Mo), and Kovar. By precisely sealing these materials, we create high-precision components for specialized medical and industrial applications, meeting a wide range of customer needs.

Housekeeper Seals: A World-Class Technology

We are one of the few companies in the world with the advanced technology to create a direct, robust seal between borosilicate glass and metals with vastly different expansion rates, such as stainless steel and copper. This rare capability is one of our key strengths.Launched in 2024, our Housekeeper Seal products are named after the technology's inventor, who pioneered a method using a thin copper edge to form a stable, hermetic joint. This allows us to produce high-quality, reliable components for the most demanding applications.

Applications: Vacuum piping for high-vacuum systems, sample containers for analytical instruments, and more.

Learn More

Vacuum Forming

We have engineered a proprietary vacuum forming process, leveraging our dual expertise in vacuum systems and precision mold shaping. By inserting a mold into a glass tube and applying a vacuum, we can produce components like high-precision glass cells (cuvettes) that meet diverse and demanding specifications.

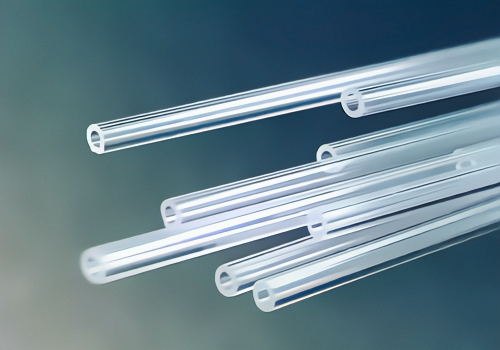

Drawing ProcessMastering Micro Shape

Our glass drawing technology allows us to produce micro-tubing with complex profiles beyond the conventional round shape, including square and hexagonal cross-sections. Using Grade 1 hard glass (borosilicate), we can achieve precise dimensions, with past examples including tubes with an outer diameter of 1.0 mm and an inner diameter of 0.6 mm. We also fabricate custom profiles to meet specific client requirements.

Our Commitment to Innovation

We are dedicated to advancing our processing technologies through continuous research and development to meet evolving market needs. Our manufacturing capabilities for technologies like Housekeeper Seals represent a rare and highly advanced skill set possessed by only a handful of companies globally. Our mission is to preserve and pass on this valuable expertise, building a bridge to the future by delivering high-precision, quality products our customers can trust.

Stem Terminals

We are developing new manufacturing processes for stem terminals to ensure both the continuation of our technical heritage and a stable supply for our clients. This modern approach overcomes the supply instabilities of traditional methods, allowing us to serve a broader customer base. Our new process yields components that maintain high reliability even in harsh conditions, meeting the needs of diverse industrial applications.

Applications: Components for supplying electricity inside sealed glass vessels such as X-ray tubes, vacuum tubes, and specialty lamps.